While there are many interesting works focusing on novel fabrication machines for the production of architecture the aim of my effort was to explore the processes necessary for an increase in automation.

While there are many interesting works focusing on novel fabrication machines for the production of architecture the aim of my effort was to explore the processes necessary for an increase in automation.

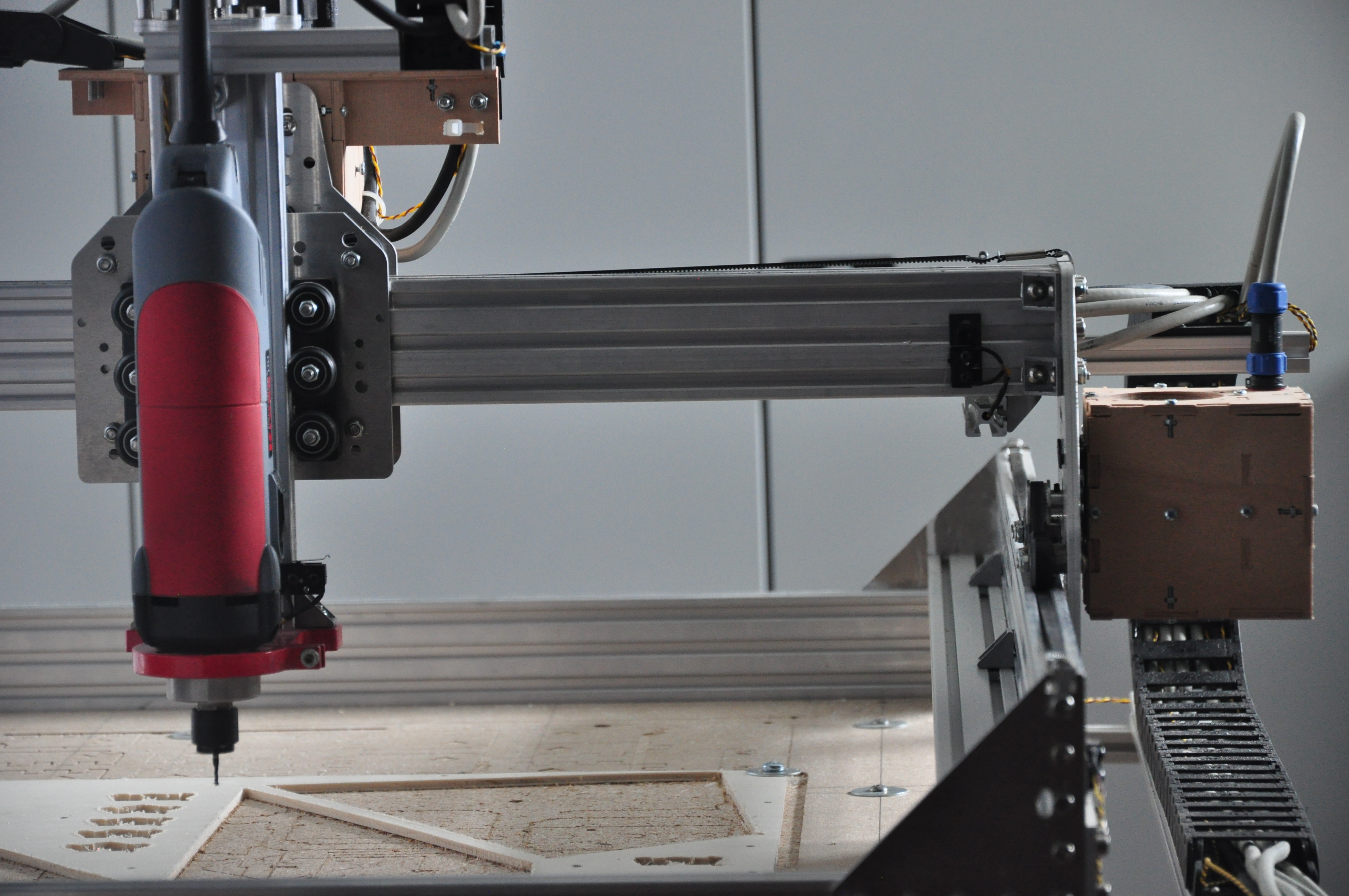

The capabilities of this self built open source CNC router were the boundaries for the physical result of my model process.

The traditional process goes something like this.

The traditional process goes something like this.

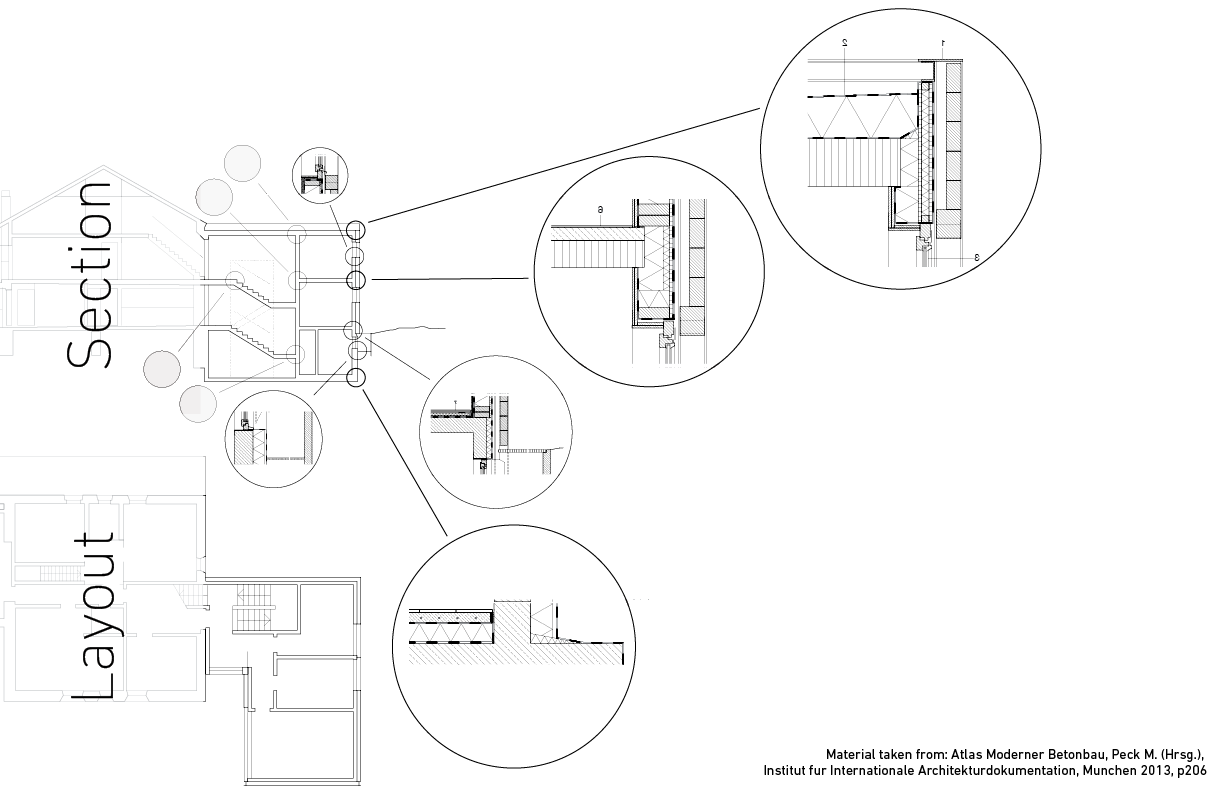

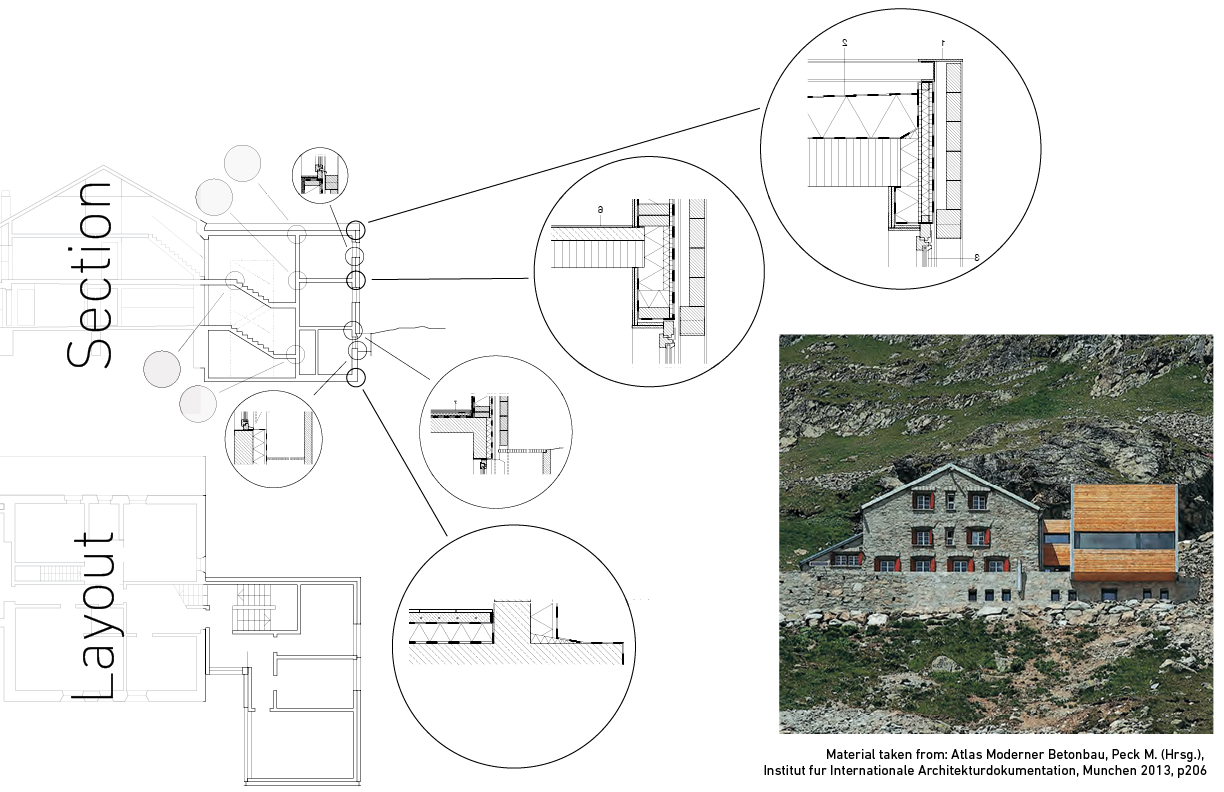

You think of spaces and draw them in Sections and Layouts. In this case for an Annex to an Alpine Refuge. Next you go down to smaller and smaller scales drawing details defining the construction of walls, ceilings and structural elements.

Next you go down to smaller and smaller scales drawing details defining the construction of walls, ceilings and structural elements.

And then you give attention to the transition of layers of material at nodes between different parts.

And then you give attention to the transition of layers of material at nodes between different parts. Which is then built.

Which is then built. For my experiment I changed this sequence.

For my experiment I changed this sequence.

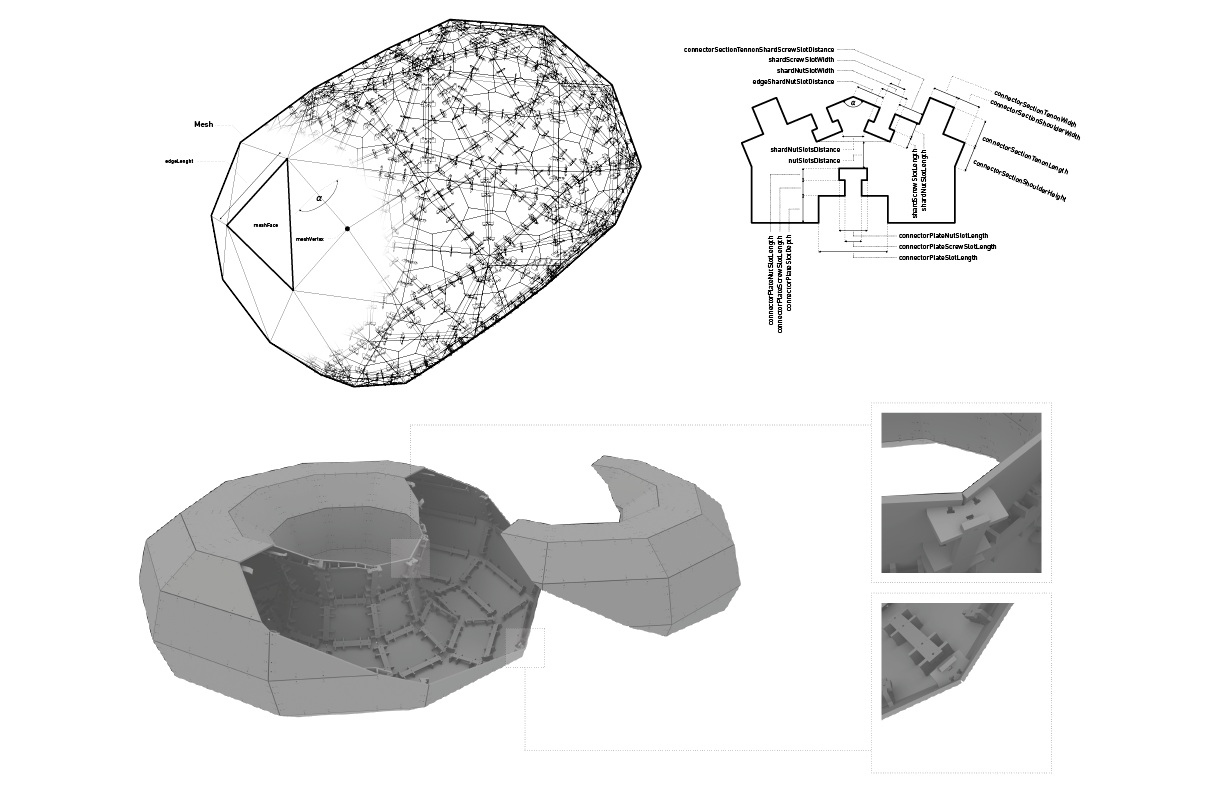

I started by defining a construction that is applicable for a certain range of components and connections.

These definitions I expressed through code so that they became easily applicable to any geometry within the set ranges.

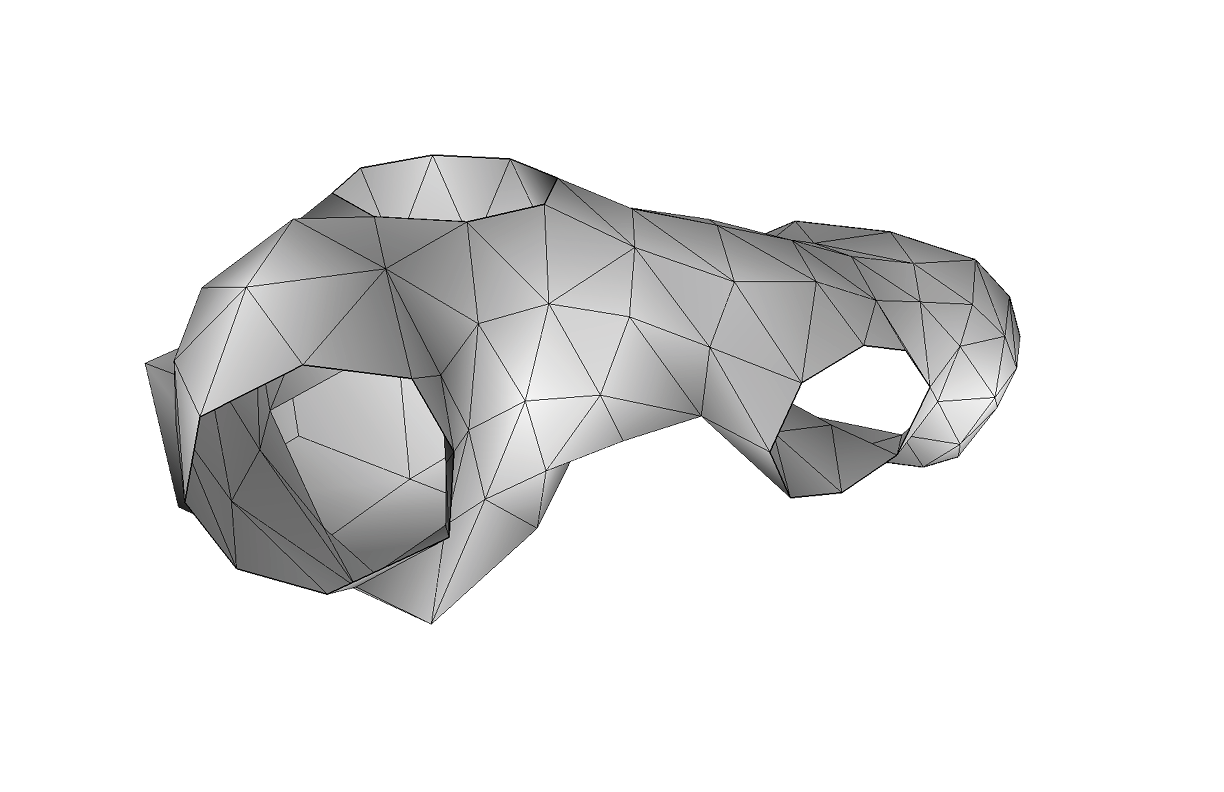

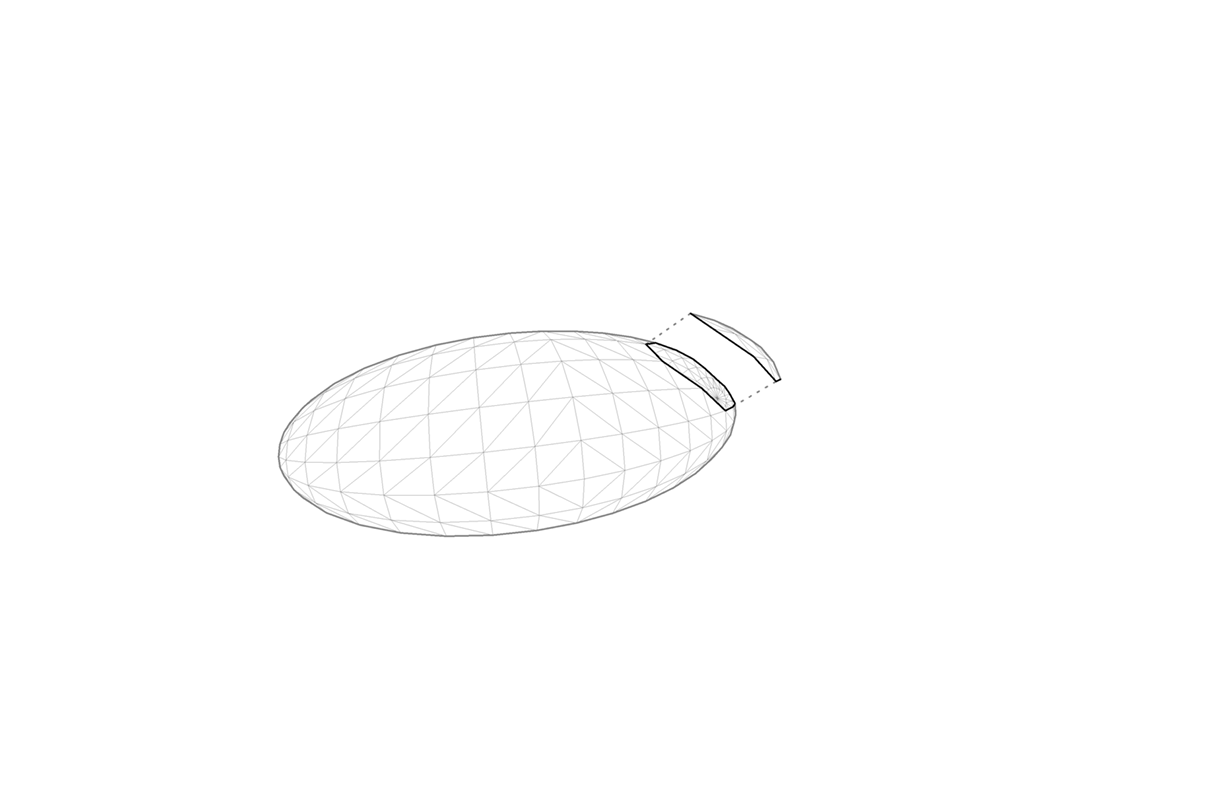

Only then I started designing the artifact to be produced.

Only then I started designing the artifact to be produced.

At every step I could get feedback about the parts that would have to be CNC milled and the exact numbers of fasteners that would be necessary for putting the whole thing together.

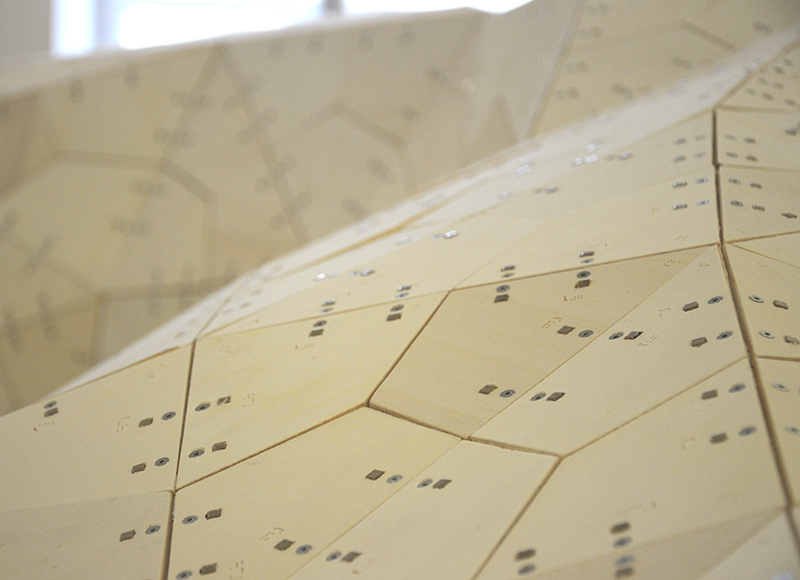

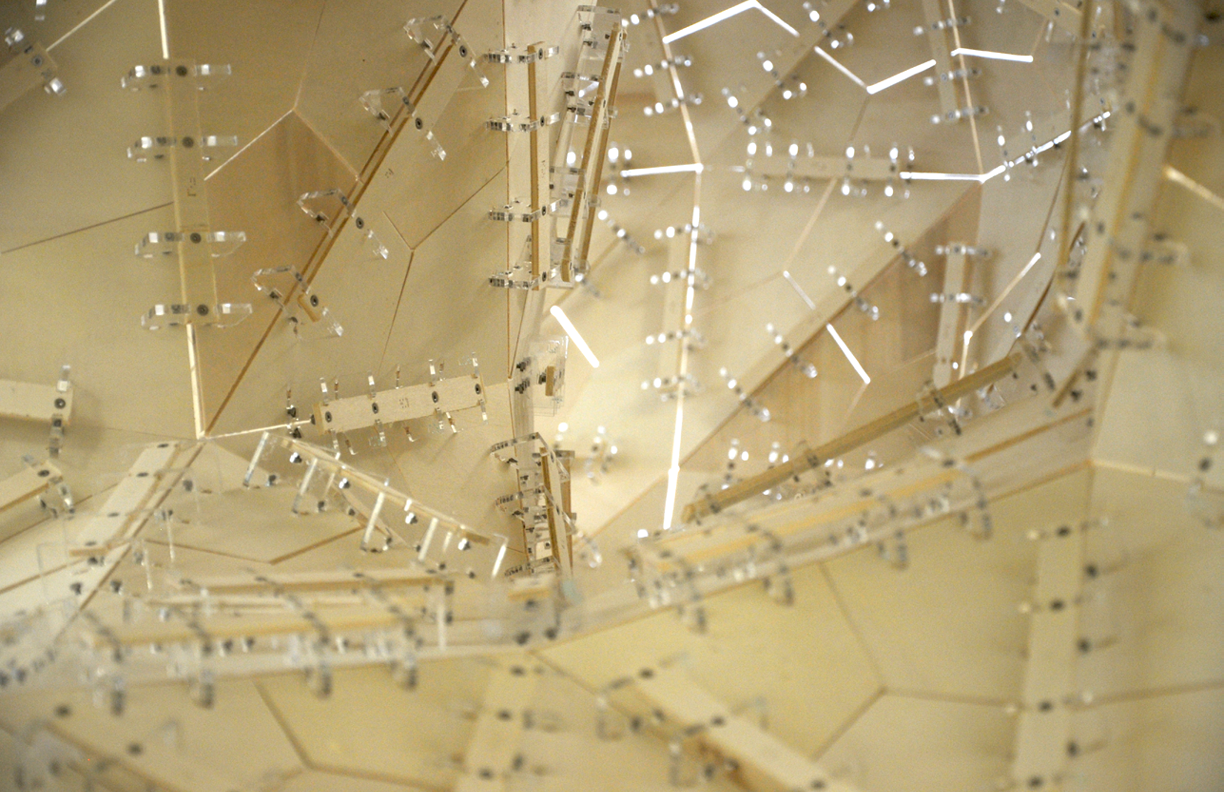

Several thousand custom parts were then cut and almost 10 thousand nuts and screws used

Several thousand custom parts were then cut and almost 10 thousand nuts and screws used

to form the physical result of the process.

to form the physical result of the process. The process of fabrication had several stages. In a first effort all parts generated by the algorithm were cut from plywood and acrylic. As there were over two thousand unique parts they had a code milled into them for identification.

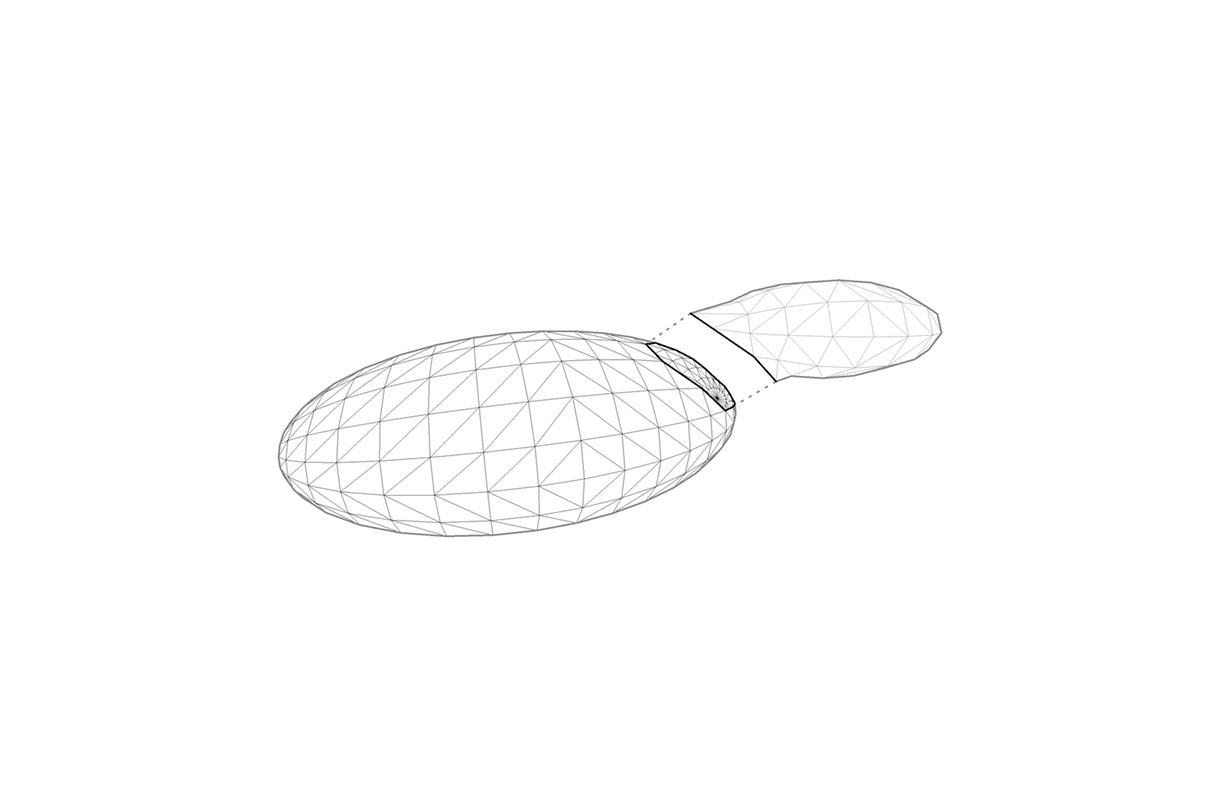

The process of fabrication had several stages. In a first effort all parts generated by the algorithm were cut from plywood and acrylic. As there were over two thousand unique parts they had a code milled into them for identification. They were then combined into modules. The modularization in this process is loosely based on ideas from objet oriented programming. Contrary to common architectural modules they were not physically identical. Similar to objects in software each module had its unique shape but was created using the same set of rules.

They were then combined into modules. The modularization in this process is loosely based on ideas from objet oriented programming. Contrary to common architectural modules they were not physically identical. Similar to objects in software each module had its unique shape but was created using the same set of rules. Interconnections happen along modules’ interfaces that define the geometrical conditions that have to be met for a connection to be possible. On a meta-level these interfaces also handle the exchange of physical loads and if you spin this further possibly electricity, air and water.

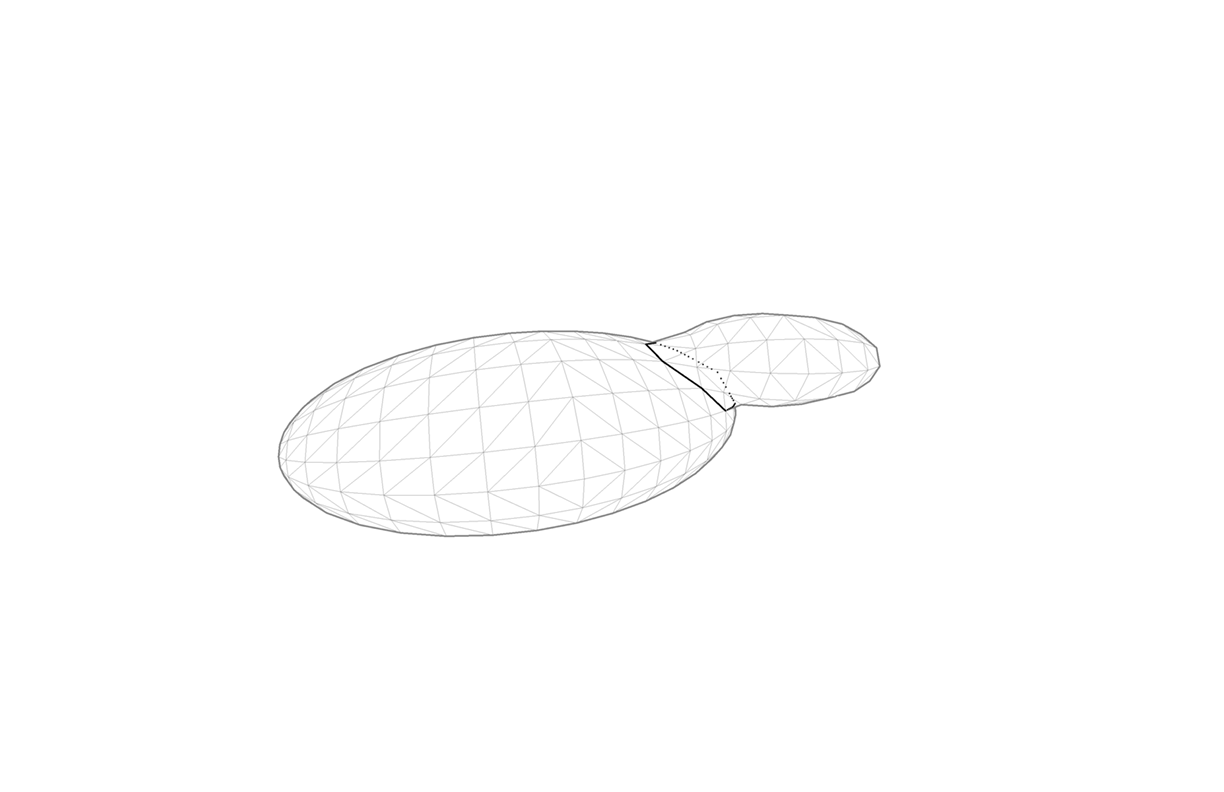

Interconnections happen along modules’ interfaces that define the geometrical conditions that have to be met for a connection to be possible. On a meta-level these interfaces also handle the exchange of physical loads and if you spin this further possibly electricity, air and water. As all parts are interconnected only by non permanent means like screws

As all parts are interconnected only by non permanent means like screws

any subset of parts can be removed and has a combined interface with the remaining set.

any subset of parts can be removed and has a combined interface with the remaining set. After removal it can be replaced easily with any other set that satisfies the conditions of the available interface

After removal it can be replaced easily with any other set that satisfies the conditions of the available interface making a system that is set up in such a way highly flexible.

making a system that is set up in such a way highly flexible. All the different types of parts of the structure are the results of modules of the code. Swapping them could make the structure stronger or change the material used. Give the shell an additional layer of insulation or a layer of electric wiring.

All the different types of parts of the structure are the results of modules of the code. Swapping them could make the structure stronger or change the material used. Give the shell an additional layer of insulation or a layer of electric wiring.

Open source software is possibly the most complex and fruitful team effort humanity has ever achieved. Using code to create architecture also allows us architects to directly use the tools and experience that go into open source software to create a positive impact on the life of anyone who has access to a Fab-Lab. And while it will not be so easy to use a system like the one i modeled in my work for building a skyscraper it is well within the realm of feasibility to use a version of it to help improve the security of built environments like these,

And while it will not be so easy to use a system like the one i modeled in my work for building a skyscraper it is well within the realm of feasibility to use a version of it to help improve the security of built environments like these,  make towns like that one more interesting

make towns like that one more interesting  or give people like these refugees who have been pouring into Austria and many other places all over Europe in the course of the last months who don’t even have a roof over their head the means to create shelter for themselves and at a higher quality in a more sustainable manner.

or give people like these refugees who have been pouring into Austria and many other places all over Europe in the course of the last months who don’t even have a roof over their head the means to create shelter for themselves and at a higher quality in a more sustainable manner.